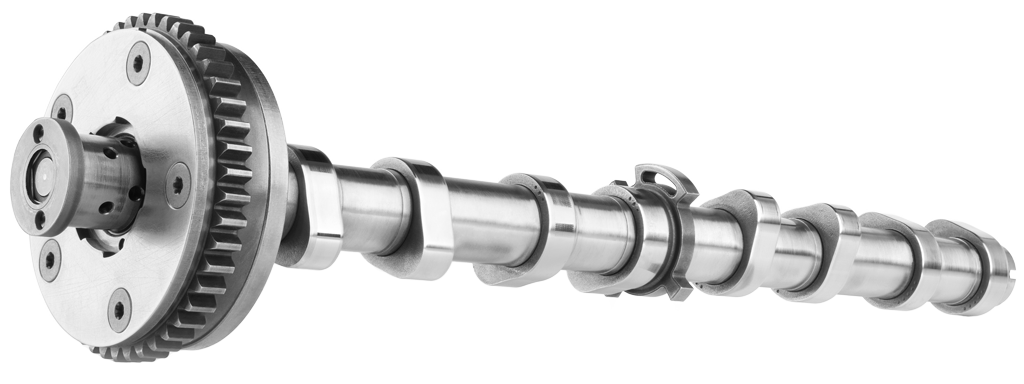

Alfa Romeo 2,0 16V /Regrind standard camshafts

product properties

| Product number: | 01.046.001U |

|---|---|

| Manufacturer: | Alfa Romeo |

| Valve timing: | 20/60 - 60/20 |

| Variant: | Regrinding of standard camshafts |

| enginetype: | 2,0 16V |

| Application: | Street |

| Duration: | 260° |

| Peak timing: | 110° |

| Lift at TDC: | 1,2 |

| Valve lift: | 10,3 |

Regrind standard camshafts Alfa

155 / 156 / GTV / Spider 2,0 16V hydro

Applikation : Road

Duration: : 260

Peak timing: : 110

Valve lift: : 10,3

Lift at TDC: : 1,2

Valve timing: : 20/60 - 60/20

Valve clearence: : ---

Some information on our camshaft program.

For a easy select, we chose four different camshaft categories. The categories show our recommendation for the application area of the car.

Road : This cam type is designed to installed into a standard produktion road car. No other modifications are necessery.

Sport : This cam type is designed for the sporty driver. We recommend the use of a ajusted chip.

Rallye : This cam type is designed for rally or slalom competition cars. We recommend the use of twin carburators or multi throttle injection systems with this cam type.

Oval track :This cam type is designed for long-time-race-, hill-climbing- and dragster- competition cars.

In principle, all camshafts are on stock and ready to be delivered.

Some camshafts require reinforced valve springs. For this, we have developed valve spring sets made of high quality materials. We ask of you to inquire the necessity of reinforced valve springs The part number under "Spring set" includes all necessary parts like bearings, spring seats etc. Single components can be supplied on inquiry.

When ordering, please state the complete vehicle data and what it will be used for, for example the road, rally, oval track, etc.

When exchanging the camshaft, be sure to also exchange all parts that come into contact with it, ( for example the dumping lever, tappets, valve adjustment plates) to ensure that the camshaft surface won\'t be damaged. We offer dumping levers made of improved materials especially for Opel-OHC-camshafts.

All camshafts are delivered with exact installation guide and data, and, if not specified differently, are to be built in like the standard camshafts.

It was our intention not to list all vehicles by name to avoid confusion. As said at the beginning, we can regrind the standard camshafts for nearly all vehicles at home and abroad, if there are no blanks available.

Es ist nicht immer möglich mit diesem Prinzip den Nockenhub zu bestimmen, da nicht immer bekannt ist an welcher Stelle die Nockenrampe beginnt und endet.

Deshalb sollte die Nockenwelle zwischen Spitzen mit einer Messuhr vermessen werden. Dabei müssen die Zentrierungen der Nockenwelle zu den Lagerstellen laufen, so dass diese keinen Höhenschlag aufweisen.

2. Da es etwas schwer zu verstehen ist, wie durch Umschleifen der Nockenhub erhöht werden kann, wird dies an dieser Stelle erklärt.

Wie in Bild 2 zu sehen ist, wird der Grundkreisdurchmesser reduziert.

Nachdem das Ventilspiel eingestellt wurde, sitzt der Nockenfolger näher an der zentralen Achse der Nockenwelle. Das Verhältnis von Nockenhöhe und Grundkreisdurchmesser hat sich verändert.

3. Die Spreizung ist der Winkelabstand der Kurbelwelle vom oberen Totpunkt des Kolbens bis zum maximalen Hub des jeweiligen Ventils.

4. Der Hub im OT (oberer Totpunkt) oder anders die Ventilüberschneidung, ist das Maß um das die Ein- und Auslassventile geöffnet sind, während sich der Kolben im oberen Totpunkt befindet.

5. Die Steuerzeiten sind die Kurbelwinkelgrade bei denen sich das Ein- und Auslassventil öffnet und schließt.

Performance camshafts

dbilas dynamic manufactures and develops both camshafts and the entire valve train.

Our valve train components are produced on our CNC machining centres after prior modelling with the latest CAD/CAM software.

We are able to calculate profiles on request, so that every customer requirement can be fulfilled.

In order to cover the widest possible range of vehicles and applications, we manufacture camshafts from both chilled cast iron and various heat-treatable steels. Our sports camshafts are also optimised during development with the help of flow technology on our flow bench.

If you cannot find what you are looking for in our camshaft range, we can calculate and implement your desired profile. But we can also supply special valve springs, tappets and parts to compensate for valve clearance.

We have the possibility to regrind standard camshafts for almost every vehicle at home and abroad, if no blanks are available. After regrinding, the camshafts are subjected to a hardness test and, if necessary, nitrided. Please also ask us for suitable accessories. We will be happy to make you an offer!

When selecting the regrinding of the standard shafts, it is necessary to send us the standard shafts. For this purpose, the following linked form is required.

PDF order-for-processing:-regrinding-of-camshafts